Westmont's Water Jet

August 4, 2022

Complex Transload Facility Project: Phase 1

September 1, 2022Method for Extending Building Columns for 2nd Level

Recently, Westmont was working on a job site that required an extension welded to an existing column for a second level of steel framing. The existing column was located tight against the outside masonry wall, was covered by an interior masonry mullion and had support steel attached on two sides. This made welding nearly impossible even with demolition of the interior and outside wall and parapet.

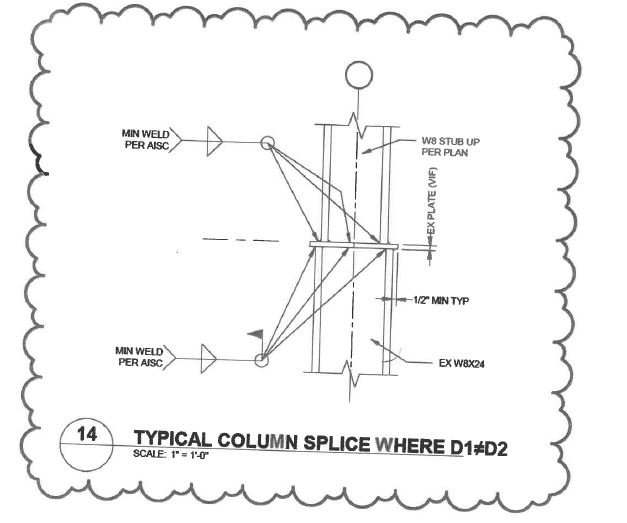

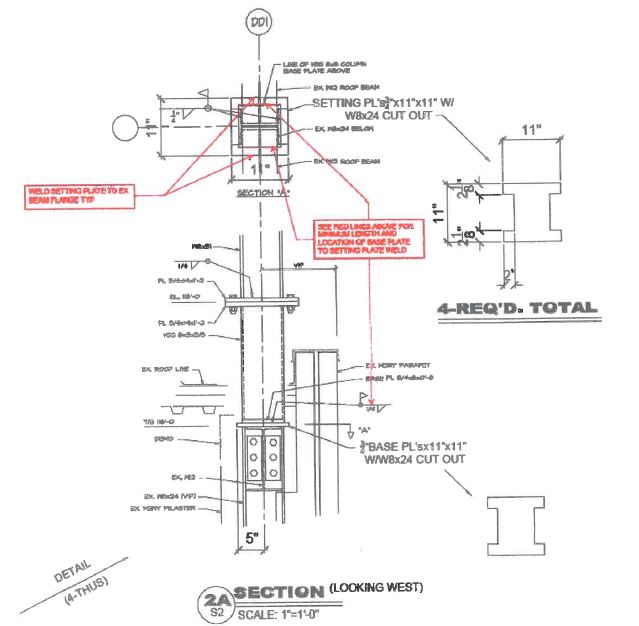

We contacted the engineer of record and suggested the following procedure as an alternative. We fabricated a setting place cut to allow fillet welding to the top of the existing column flanges and weldable to the top of the two existing connecting beams. (The top of the column was flush with the top of the connecting beams.) We prefabricated tube stub columns with baseplates and then field welded the base plates to the setting plates. We decided to install a prefabbed tube stub column to make roof flashing easier and reduce the roofing time required. We then shot the top of the stub columns shop fabricated a new column designed for correct elevation, and bolted the new fabricated columns to the stub column. The engineer of record agreed with the procedure saving the cost of masonry and parapet demolition and simplifying the roofing required.

The Setting plate shown in the photo above is slid to one side to expose existing column flange.